◉Project Name - Stable stage with a wide range of applications

◉City - Virgin Islands

◉Products

◉Project Profile

The Quest for a Versatile, Stable and Cost-Effective Stage Solution

In the dynamic world of event planning and staging, the need for versatile equipment that can adapt to various terrains and scenarios is paramount. Customers are increasingly seeking a stable, adjustable table leg height solution that not only meets their functional needs but also fits within their budget constraints. This article takes a deep dive into balancing the triangle of quality, price and functionality and how it can revolutionize the way staging is built for numerous events.

◉Design Requirements

The customer needs a design that can adjust the stage height to adapt to various terrains, while ensuring structural strength and saving procurement costs. This way, it can adapt to various terrains and appear in various performances. In order to achieve this goal, we considered many options and finally decided to use an assembled stage. This stage has a simple structure and consists of five parts: stage board, stage frame, brace, telescopic aluminum tube column and adjustable base. By adjusting the height of the base and the 6mm thick telescopic aluminum tube, the 500mm height can be freely adjusted. At the same time, the 6mm thick telescopic aluminum tube, stage frame and brace ensure the structural strength. There are stage slots on the brace and the stage legs, adjustable base and brace can be shared when assembling multiple stages. Buy more and save more.

◉Structural Design

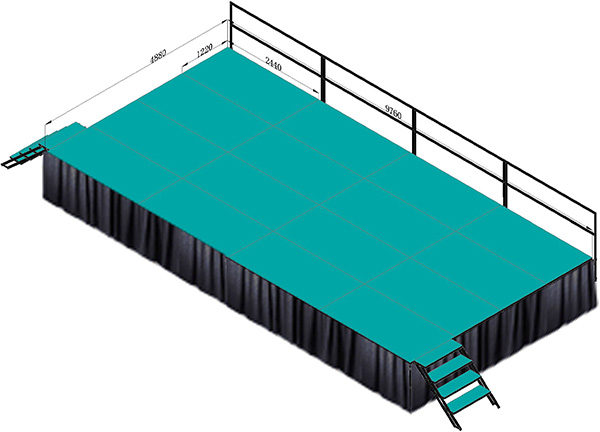

The assembled stage consists of a stage board, a stage board frame, 4 stage columns, 4 adjustable bases and 4 braces. In addition, for the convenience and safety of going on stage, steps and guardrails made of the same aluminum alloy are generally configured. For the sake of beauty, you can also choose a black stage apron to unify the stage visual effect.

In order to ensure stability and height adjustability, we have added brace, adjustable bases and telescopic aluminum tube columns on the basis of traditional legs, stage frames, stages and necessary fasteners. The height of the base and telescopic aluminum tube columns can be adjusted during installation, with an adjustment range of 0-500mm. The conventional sizes of stage boards are 1.22*1.22 meters and 1.22*2.44 meters and are usually made of waterproof and non-slip 18mm thick plywood. The advantage of the 1.22*1.22 stage is that it can be flexibly assembled into stages of various sizes. The advantage of the 1.22*2.44m stage is that it is relatively affordable and the height can be customized according to customer requirements. The conventional adjustable heights are 0.4-0.6m, 0.6-1m, 0.8-1.2m, 1-1.5m and 1.5-2m. It can also be made into a fixed height. In addition, you can also customize transparent tempered glass and acrylic stage panels and special-shaped stages, such as round, to achieve extraordinary performance effects.

◉Stage Accessories Calculation Formula

Divide the total length and total width of the product by 1.22 respectively and you can get the number of stages with a length and width of 1.22*1.22 meters.

For example, if a customer wants a 20*10 meter stage, 20*1.22=16 sheets, 10*1.22=8 sheets

Then the length needs 16 sheets and the width needs 8 sheets.

Assume that we use A to represent the number of stages required for length and B to represent the number of stages required for width, A*B=16*8

Stage panel including frame = A*B=16*8=128 pieces

Assembly stage brace/monolithic = (A+1)*B+A*(B+1)=17*8+16*9=280 pieces

Assembly stage column and adjustable base = (A+1)*(B+1)=17*9=153 pieces

Volume calculation: 1.22*2.44m face frame packaging volume = 1.23*2.45*0.06m

1.22m single piece packaging volume = 1.23*height*0.06m

Leg packaging volume = minimum height*0.06*0.06m*2

◉Customer Evaluation

This product has a good balance of function, quality and price,and is a solution that is worth promoting.We hope there will be more and more professional products like this.

Contact Us Today

11

Founded 11 years ago

155

Exported to 155 countries

12600+

Served 12600+ customers

10000

Built a 10,000 ㎡ automated factory