23 Aug 2023

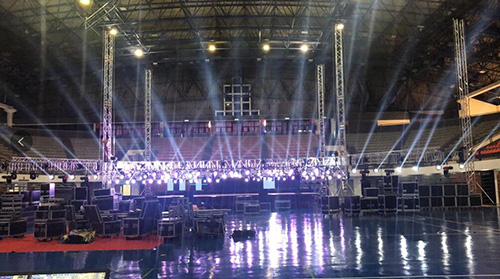

In our daily performances, commercial performances and some wedding industry, in order to maximize the program to attract the audience's attention, also need a lot of hard work, each stage should build out of each light, each sound, have to make the audience bright in order to achieve good program results,the cost of light and sound set up are also Need to be carefully calculated in order to maximize the benefits, the following small series will give Everyone brings some tips and locations for the stage to introduce to you, for your reference only.

Stage lighting construction process:

1. Truss base: placed at the bottom of the aluminum alloy lighting frame pillar, used to support the pillar truss, the adjustable foot cup structure under the base, adjustable height, very useful for the uneven ground venue. Use the screw to connect the upper head and insert the four holes around. The horizontal extension of the diagonal support (black).

2. Truss hinge: A 1 m truss with a loose-leaf connection in the middle, the upper part can be rotated 180 degrees along the connecting axis. The function of the hinge head is to facilitate the construction of the pillar truss. For the particularly high pillar aluminum alloy lighting frame, if there is no hinge , it is necessary to assemble each pillar frame by a ladder and other tools, but the hinge is very Simple and convenient, first link the pillar aluminum alloy lighting frame flat, then connect one end of the aluminum alloy lighting frame to one end of the reverse head, the bottom end of the reverse head is fixed on the base and then several people together put the pillar truss to Supported.

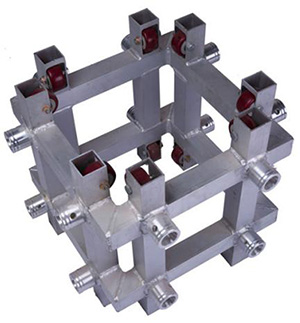

3. Truss sleeve block: The function of the sleeve is to connect the pillar aluminum alloy lighting frame and the beam aluminum alloy lighting frame. When the chain hoist is used to move the sleeve, the beam can be moved up and down. The inside of the sleeve is provided with a pulley so that the sleeve can slide vertically along the direction of the pillar. The sleeve is different from the six-sided joint. After the six-sided joint is connected to the beam, it cannot move up and down and the sleeve can be moved.

4. Truss Top-section: The role of the cross arm is to fix the upper end of the chain hoist, which should bear the most force, so it is generally made of steel. When using, screw the cross arm to the top of the pillar truss, then hang the chain hoist on the top.

Through continuous research and practice, We have formed our own set of technical service modes in multimedia audio-visual system integration and equipment leasing. After years of development, SGAIER TRUSS is also a professional manufacture company with strong technical strength and humanized comprehensive service capabilities.

Keywords: truss

Originally published 23 Aug 2023, updated 23 Aug 2023.

11

Founded 11 years ago

155

Exported to 155 countries

12600+

Served 12600+ customers

10000

Built a 10,000 ㎡ automated factory